Our booths aid in providing a clean and healthy work place. Modified downdraft paint booths are not only easy to maintain, they can also be pressurized by ambient air or by a heated air make-up unit with a cure cycle. This style booth intakes fresh air from the cleaner upper levels of the shop through a secondary set of filters located in the plenum before entering the booth ceiling filters near the product doors. The filtered air is drawn down through the booth to an exhaust filter system at the opposite end of the booth.

Our modified downdraft paint booth line is offered in a several standard sizes and configurations, which include pressurized, non-pressurized, solid back, reverse flow and drive thru designs.

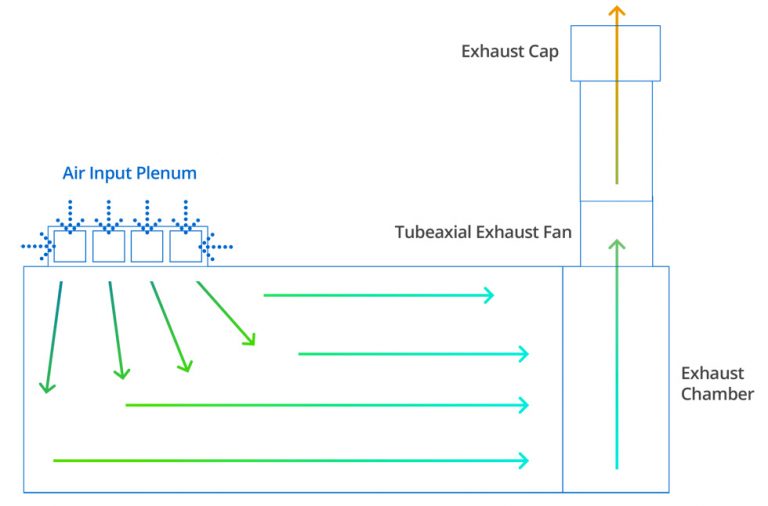

Clean air flows into the prefiltered intake plenum (located in the roof toward the front of the booth), moves downward passing through the work area, and exits through the exhaust plenums located in the rear of the booth. Filtered exhaust air is drawn thru the exhaust plenums and discharged upward into the atmosphere through the exhaust stacks. This booth is provided complete, with all necessary hardware to meet the applicable national requirements established by OSHA, and the NFPA for paint booth construction.

Our factory trained installation crew can get your new Modified Downdraft Paint Booth installed correctly and quickly.

This our specialty! You can rest assured that your new equipment will be operational in no time.

The sizes listed below are standard catalog sizes. We can custom build all of our finishing equipment to meet your needs. Call us at 800-637-4027.

| Interior Dimensions | Exterior Dimensions | Access Doors | Nominal Door Opening | Lights | Air Flow | ||||||||

| Width | Height | Length | Width | Height | Length | Width | Height | Qty | Type | Open | S&G | SCFM | |

| 14′ | 9′ | 26′ | 14’6.5″ | 10’10” | 26’4″ | 1 | 9’4″ | 8’10.5″ | 1 | Solid | 9 | 1 | 12,600 |

| 14′ | 9′ | 26′ | 14’6.5″ | 10’10” | 26’4″ | 1 | 9’4″ | 8’10.5″ | 1 | Solid | 9 | 1 | 12,600 |

This booth intakes fresh air from the filtered front doors it. The air is pulled across the parts being painted to the exhaust filter bank located at th e rear of the booth. The air is then filtered and exhausted in through the duct work.

All Our Booths NOW Have LED Lighting!

Fixtures are Maintenance-Free rated for Class I Division II Groups A, B, C, D; Class II Division II Groups F & G. Fixtures are ETL listed and approved for their intended use and placement. Lighting is provided by innovative LED technologies consisting of multiple high efficiency flux boards paired with high efficiency drivers. Fixtures are designed to accept either 120VAC or 277VAC power. Drivers and boards carry a 5-year limited warranty. To find out more about LED light fixtures, please click here.

© Copyright 2024 – Paint Booth | Terms & Conditions | Managed by Inersche