Why Should We Use a Sandblasting Booth Over Outdoor Blasting?

Outdoor sandblasting comes with risks like weather disruptions, dust exposure, and inconsistent results. A sandblasting booth offers a safer, cleaner, and more efficient solution, ensuring superior quality and environmental compliance. Find out why it’s a game-changer for your business.

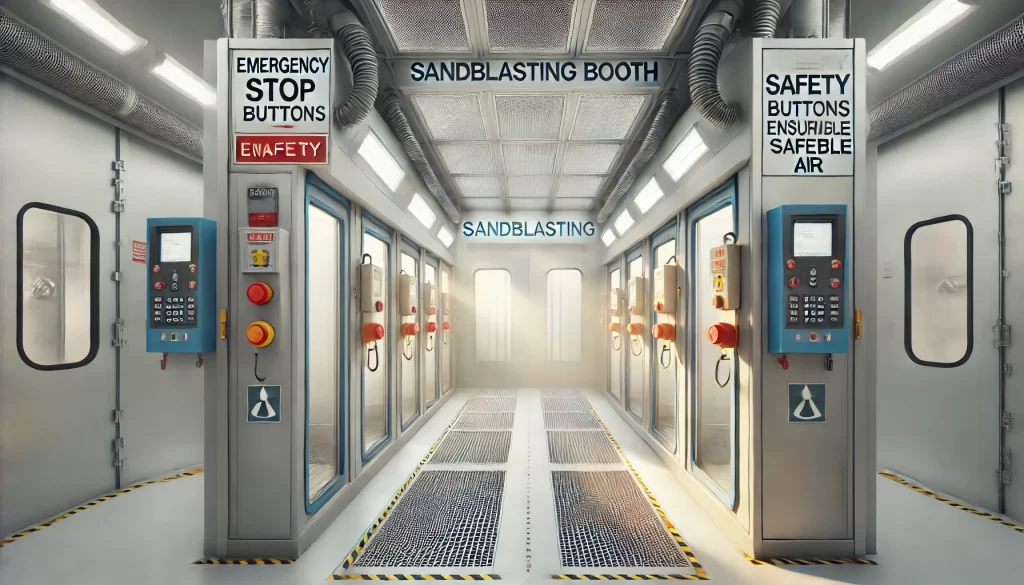

How Do Sandblasting Booths Ensure Operator Safety?

Sandblasting booths are designed with safety in mind, protecting operators from hazardous dust, noise, and vibrations. Learn how features like dust collection systems, protective gear compatibility, and emergency shut-offs keep workers safe and productive.

Are Sandblasting Booths Environmentally Friendly?

Modern sandblasting booths have come a long way from being major environmental hazards. With innovations like dust filtration, abrasive recycling, and energy-saving systems, they’re now eco-conscious solutions for industrial surface preparation. Find out how sustainable practices can further reduce their environmental impact.

How Do Sandblasting Booths Manage Dust and Debris?

Sandblasting generates dust and debris, making proper management essential for safety and efficiency. Learn how sandblasting booths use containment, filtration, and recovery systems to maintain a clean and safe working environment.

What Industries Commonly Use Sandblasting Booths?

Sandblasting booths play a crucial role in industries like automotive, aerospace, marine, and construction. Discover how these industries use sandblasting booths for cleaning, rust removal, and surface preparation, ensuring durability and precision.

How Do Paint Booths Control Overspray and Emissions?

paintbooth.coms are essential for managing overspray and reducing emissions in automotive and industrial painting. Learn how they use advanced airflow systems, filters, and environmental controls to maintain clean, safe, and efficient workspaces.

How Energy-Efficient Are Modern Paint Booths?

Explore the cutting-edge features that make modern paint booths champions of energy efficiency. From advanced airflow systems to energy-saving lighting, learn how these innovations not only reduce costs but also support environmental sustainability, helping businesses thrive in a competitive marketplace.

Can a Paint Booth Be Used for Multiple Coating Types?

Is it possible to use one paint booth for different coatings like liquid paints, powders, or specialized finishes? Find out how proper setup, maintenance, and system upgrades can turn your booth into a multi-coating powerhouse.

Essential Paint Booth Filters: Types and Uses

Filters are vital in paint booths for clean air and smooth finishes. Learn about intake, exhaust, and specialty filters like HEPA and activated carbon for top-notch results.

How to Maintain Optimal Airflow in Your Paint Booth

Maintaining optimal airflow in your paint booth is vital for safety and efficiency. Regularly check filters, exhaust fans, and seals to ensure clean air and a smooth finish. Learn how to achieve perfect airflow for better results.